In today’s fast-evolving apparel manufacturing landscape, understanding the tools that power productivity is key to staying competitive. One critical tool that shapes the entire garment production process is the cutting machine. But what is a cutting machine in the garment industry, and why is it so important?

A cutting machine is a specialized device used to slice fabric layers into precisely shaped pieces based on garment patterns. These machines play a foundational role in the production of clothing, upholstery, bags, and industrial textiles—transforming fabric rolls into cut components ready for sewing. With the rise of automation, digitalization, and demand for mass customization, the technologies behind cutting machines have also advanced rapidly.

In this comprehensive guide, we’ll explore the full scope of cutting machines used in the garment industry, from traditional manual tools to high-speed automated systems like CAD/CAM cutting machines. You’ll also learn about the best fabric cutting machines for this year, how to choose the right model, and what innovations are reshaping the industry.Whether you're a small-scale fashion house or a large apparel manufacturer, this article will help you understand your options, optimize production, and stay ahead of industry trends.

Why Fabric Cutting Is Crucial in Garment Manufacturing

Before stitching begins, every garment must be carefully cut from fabric into the desired shape and size. This process—known as fabric cutting—affects everything from garment fit and material utilization to production efficiency and cost control.

Using the right cutting machine ensures:

In high-volume environments, traditional manual methods no longer meet the speed and accuracy requirements of modern buyers. That’s why the garment industry has seen a significant shift toward automated and digital cutting systems.

Types of Cutting Machine in the Garment Industry

When it comes to cutting machines, there’s no one-size-fits-all. Different production scales, fabric types, and operational goals call for different machine types. Let’s break down the most widely used cutting machines in garment manufacturing.

| Cutting Machine Name | Type | Automation Level | Common Use |

| Manual cutting machine in garment industry | Manual | Low | Sampling, prototyping |

| Straight knife cutting machine | Manual | Low | High-layer fabric cutting |

| Band knife cutting machine in garment industry | Semi-automatic | Medium | Curved and complex shapes |

| Semi-automatic cutting machine | Hybrid | Medium | Mid-volume operations |

| Fully automatic cutting machine | Automatic | High | Mass production |

| Fabric cutting machine | Varies | Low to High | General garment cutting |

| Cloth cutting machine | Varies | Low to Medium | Tailoring and small factories |

| CAD/CAM cutting machine | Digital | Very High | Smart, high-speed factories |

| Digital cutting machines | Computerized | High | Precise, automated cutting |

| Cutting machine plotter | Digital | High | Cuts and plots patterns |

| Knitting CNC cutting machine | CNC | High | Elastic and stretch fabrics |

| Woven CNC cutting machine | CNC | High | Structured woven fabrics |

| Denim CNC cutting | CNC | High | Durable materials like denim |

| Unwoven CNC cutting machine | CNC | High | Non-woven textiles |

| Gerber type cutting machine | CAD/CAM | Very High | Apparel production lines |

| Lectra type CNC cutting machine | CAD/CAM | Very High | Automotive and technical textiles |

| Bullmer type CNC cutting machine | CAD/CAM | Very High | Furniture and upholstery |

| Orox type cutting machine | CNC | High | Leather and accessories |

| YIN type cutting machine | CNC | High | Mixed material production |

Each cutting machine serves a unique purpose, depending on the production scale, automation level, and fabric type.

Manual Cutting Machines: Still Useful in Modern Fashion?

Manual cutting machines are still widely used for low-volume production, design sampling, and customized orders. The most common types are the straight knife and band knife machines.

The straight knife cutting machine is ideal for cutting multiple layers of fabric in straight lines or slight curves. It’s simple, affordable, and efficient for basic tasks.

The band knife cutting machine in garment industry is preferred for complex shapes and curved patterns, offering more control and accuracy.

Manual options are best suited for smaller workshops or companies focused on artisanal or made-to-order products. However, they require experienced operators and are not scalable for large orders.

Semi-Automatic and Fully Automatic Cutting Machines: Bridging the Gap

As demand for faster turnaround increases, semi-automatic cutting machines serve as a transitional solution. These machines feature motorized blades and assistive functions while still requiring some manual input. They’re ideal for mid-size factories scaling up from purely manual operations.

Fully automatic cutting machines, on the other hand, are designed for continuous, high-speed production. These machines can cut multiple layers of fabric at once with minimal human intervention. They’re often used in high-output environments such as large fashion brands, uniform manufacturers, and home textile producers.

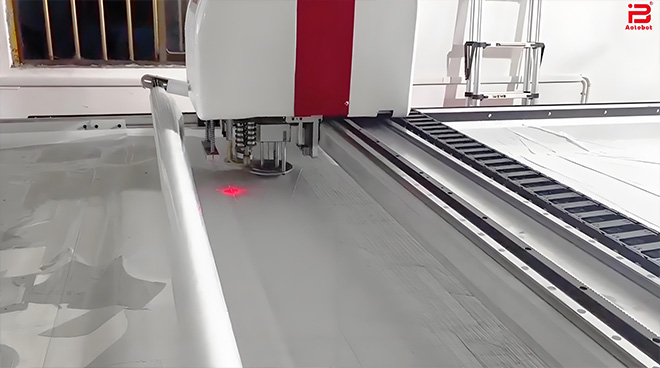

AOTOBOT’s automatic cutting systems are popular in this category, offering advanced models that reduce labor while increasing accuracy.

Digital and CAD/CAM Cutting Machines: The Future of Smart Garment Production

The most significant transformation in fabric cutting has come from digitalization. Digital cutting machines and CAD/CAM cutting machines represent the cutting edge of garment technology.

A CAD/CAM cutting machine integrates computer-aided design (CAD) and computer-aided manufacturing (CAM), allowing designers to create patterns digitally and send them directly to the cutting machine. These machines offer:

Automated nesting to reduce fabric waste

High-speed, high-precision cutting

Real-time production data

Seamless integration with ERP systems

Machines like the gerber type cutting machine, lectra type CNC cutting machine, and bullmer type CNC cutting machine are leaders in this space, widely used by global brands for their reliability and advanced software ecosystems.

AOTOBOT’s CAD/CAM cutting solutions are also gaining traction, designed to meet the needs of smart factories that prioritize flexibility, efficiency, and Industry 4.0 readiness.

Specialized CNC Cutting Machines by Fabric Category

Depending on the materials being processed, CNC cutting machines are further specialized. Here’s a breakdown of the best machines by material type:

| Fabric Type | Recommended Machine |

| Knitted fabrics | Knitting CNC cutting machine |

| Woven fabrics | Woven CNC cutting machine |

| Denim textiles | Denim CNC cutting |

| Nonwoven materials | Unwoven CNC cutting machine |

| Leather goods | Orox type cutting machine |

| Technical textiles | YIN type cutting machine |

| Automotive upholstery | Lectra type CNC cutting machine |

| Industrial furniture | Bullmer type CNC cutting machine |

These machines are engineered for specific material behaviors—such as stretch, thickness, or density—and ensure clean, accurate cuts without damaging the fabric.

Cloth and Fabric Cutting Machines: Key Differences

Although the terms cloth cutting machine and fabric cutting machine are often used interchangeably, they can refer to slightly different applications:

A cloth cutting machine may focus on lighter, woven materials and is often used in tailoring or smaller garment factories.

A fabric cutting machine has a broader range, including knits, synthetics, and technical textiles. These machines are typically industrial-grade and used in large-scale manufacturing.

Both are essential tools in the garment industry, and the choice depends on production scale and material specialization.

![Garment-1 Garment-1]()

Cutting Machines Used in the Fashion Industry

The fashion industry requires speed, versatility, and precision. As trends change rapidly, manufacturers need machines that can adapt to new styles and materials quickly. The most commonly used machines in fashion production include:

Digital cutting machines for rapid prototyping

CAD/CAM cutting machines for mass production

Fabric cutting machines for daily operations

Cutting machine plotters for visualizing and cutting design layouts

Fashion brands also rely heavily on bag cutting and accessory production, where machines must handle leather, PVC, and other durable materials with great precision.

Selecting the Best Fabric Cutting Machines in This Year

With so many choices, how do you choose the best fabric cutting machine for your business?

Here are a few factors to consider:

Production scale: For small-scale operations, manual or semi-automatic machines may suffice. For high-volume manufacturing, opt for fully automatic or CAD/CAM systems.

Material type: Choose specialized machines like woven CNC cutting machines or denim CNC cutting tools based on your fabric.

Software integration: For digital workflows, select machines compatible with common design platforms and ERP systems.

Maintenance and support: Go with a brand that offers strong after-sales support and easy access to spare parts.

AOTOBOT offers a diverse line of industrial cutting machines that cover everything from manual tools to advanced digital systems, suiting businesses of all sizes.

Industry Trends: What’s New in Fabric Cutting?

As the fashion and textile industry evolves, so do the technologies behind cutting machines. Some of the top trends include:

AI-powered cutting path optimization

IoT-enabled cutting machines for remote monitoring

Sustainable cutting techniques to reduce fabric waste

Multi-material compatibility for hybrid products

Voice-command interfaces and touchscreen controls

Many of these innovations are already featured in AOTOBOT’s latest models, positioning them as a leader in smart textile manufacturing.

FAQs

A1: What is a cutting machine in the garment industry?

Q1: A cutting machine is a tool used to slice fabric into garment components. It ranges from manual blades to automated systems like CAD/CAM cutting machines used in mass production.

A2: What are the most common types of cutting machines used in fashion manufacturing?

Q2: They include manual cutting machines, straight knife cutting machines, band knife cutting machines, digital cutting machines, fully automatic cutting machines, and CAD/CAM cutting machines.

A3: What’s the difference between digital and CAD/CAM cutting machines?

Q3: Digital cutting machines rely on computerized control for precision. CAD/CAM cutting machines go further by integrating design software directly with cutting operations for full automation.

A4: Which machine is best for cutting woven fabrics?

Q4: A woven CNC cutting machine is specifically designed for structured fabrics and ensures clean, fray-free cuts with high speed and precision.

A5: Can cutting machines be used for non-garment products like bags or upholstery?

Q5: Yes. Machines like the Orox type cutting machine and YIN type cutting machine are ideal for bag cutting and technical textiles used in furniture and automotive interiors.

A6: How many types of cutting machines are there in garment production?

Q6: There are over a dozen, including manual, semi-automatic, fully automatic, digital, and CAD/CAM systems, each with models tailored for specific materials and production needs.

A7: What is a cutting machine plotter used for?

Q7: A cutting machine plotter simultaneously plots garment patterns and cuts them. It's a key tool in digital garment workflows and pattern verification.

So, what is a cutting machine in the garment industry? It’s more than just a tool—it’s the foundation of every garment production process. From simple manual setups to smart, AI-powered CAD/CAM systems, cutting machines drive efficiency, consistency, and creativity across the apparel supply chain.

Whether you're producing t-shirts, high-fashion garments, bags, or industrial textiles, the right cutting machine can dramatically improve your output and reduce costs. Brands like AOTOBOT are leading the charge with intelligent, scalable machines that meet the demands of modern fashion manufacturing.As the industry continues to shift toward automation and digitalization, investing in the right cutting technology is not just an upgrade—it’s a necessity for staying competitive in the global textile marketplace.