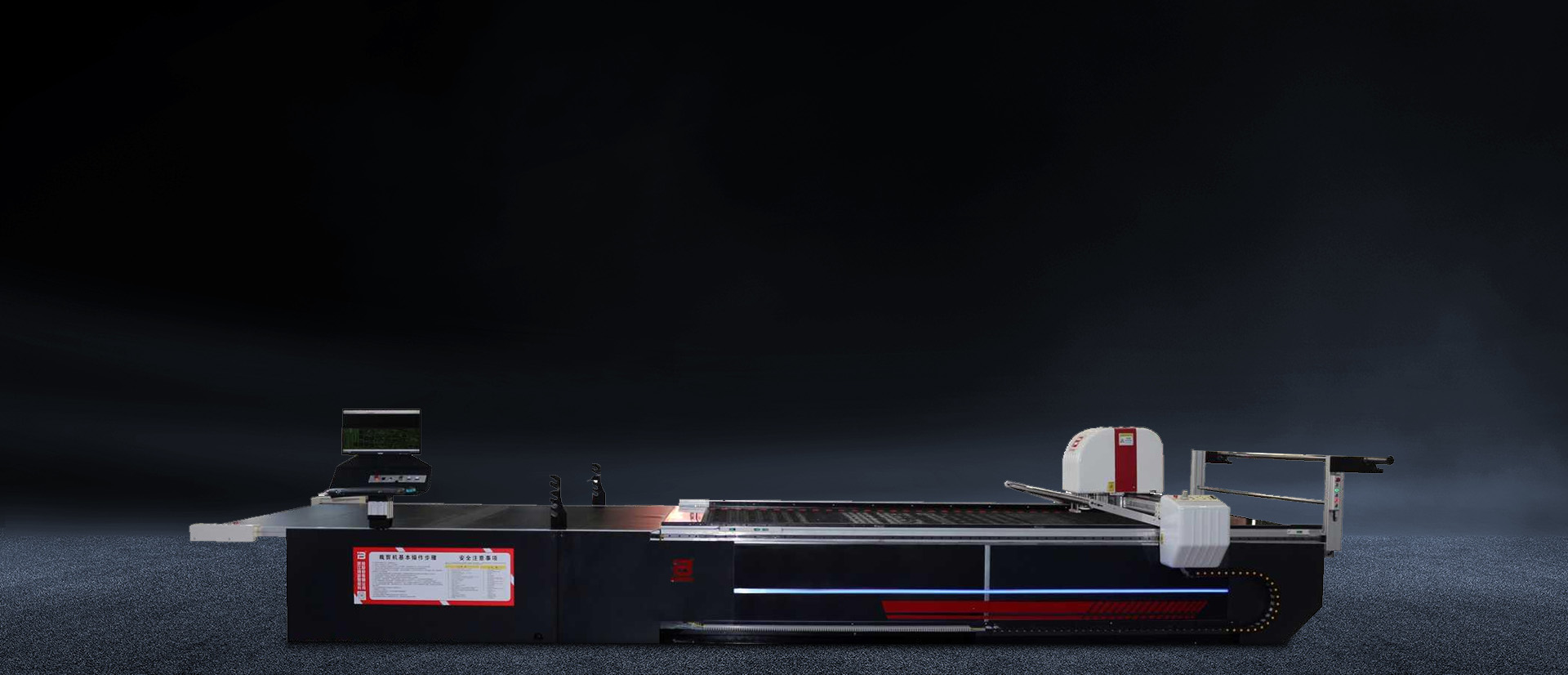

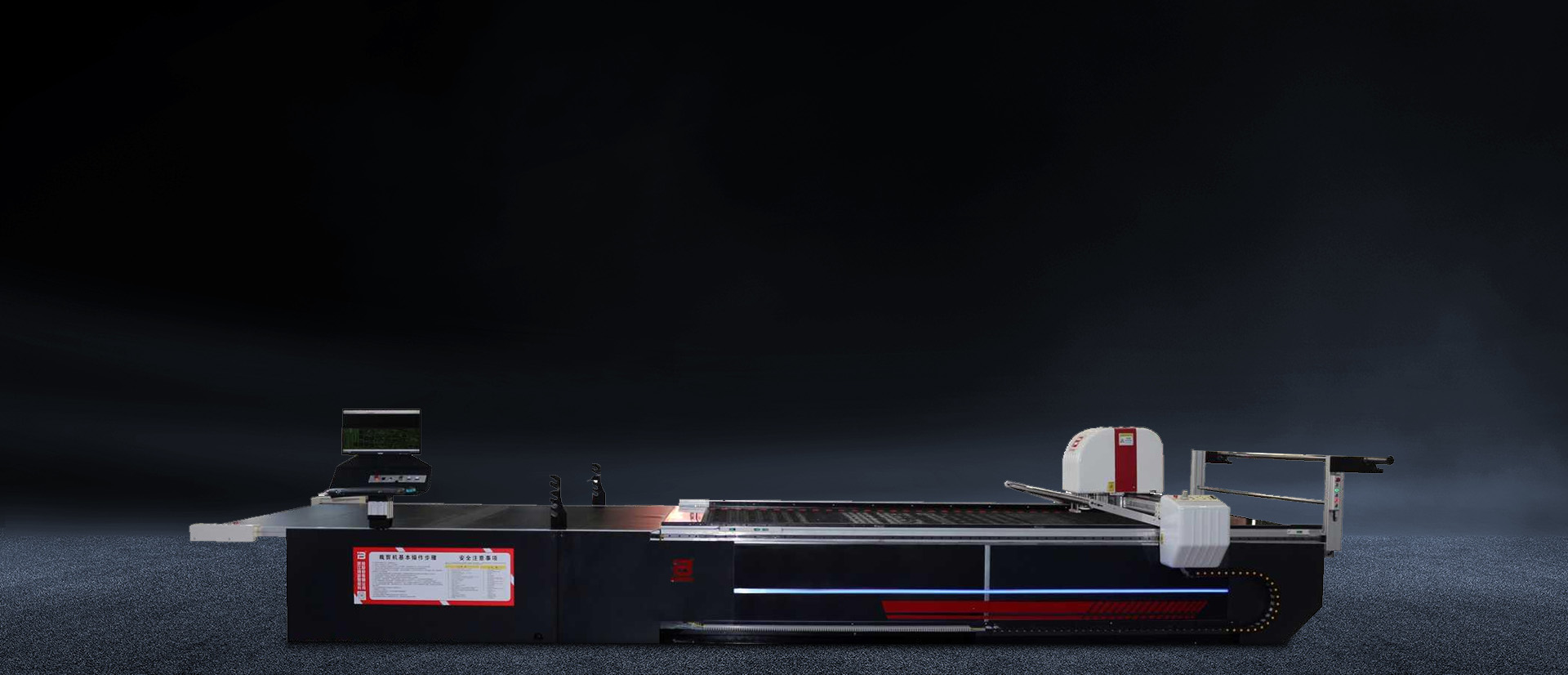

◉ Feature1 Cutting speed 108m/min; industry leading, 160-200 sets of whole car seat cover per day

◉ Double knife disc cutting, high precision, V cutter two shoulders at the same height, other brands are difficult to achieve

◉ Double knife disc cutting, strong stability, very little mechanical wear and tear

◉ Table length of 3.3 meters without loss of cutting speed, can effectively improve the efficiency of 5% work

◉ Low cost of use, excluding blades, paper, film consumables, not more than 20,000 a year

◉ Support optional 3 hollow perforation

◉ Open design, with all the optional functions of the cutting machine

Advantageous Features

LD8001

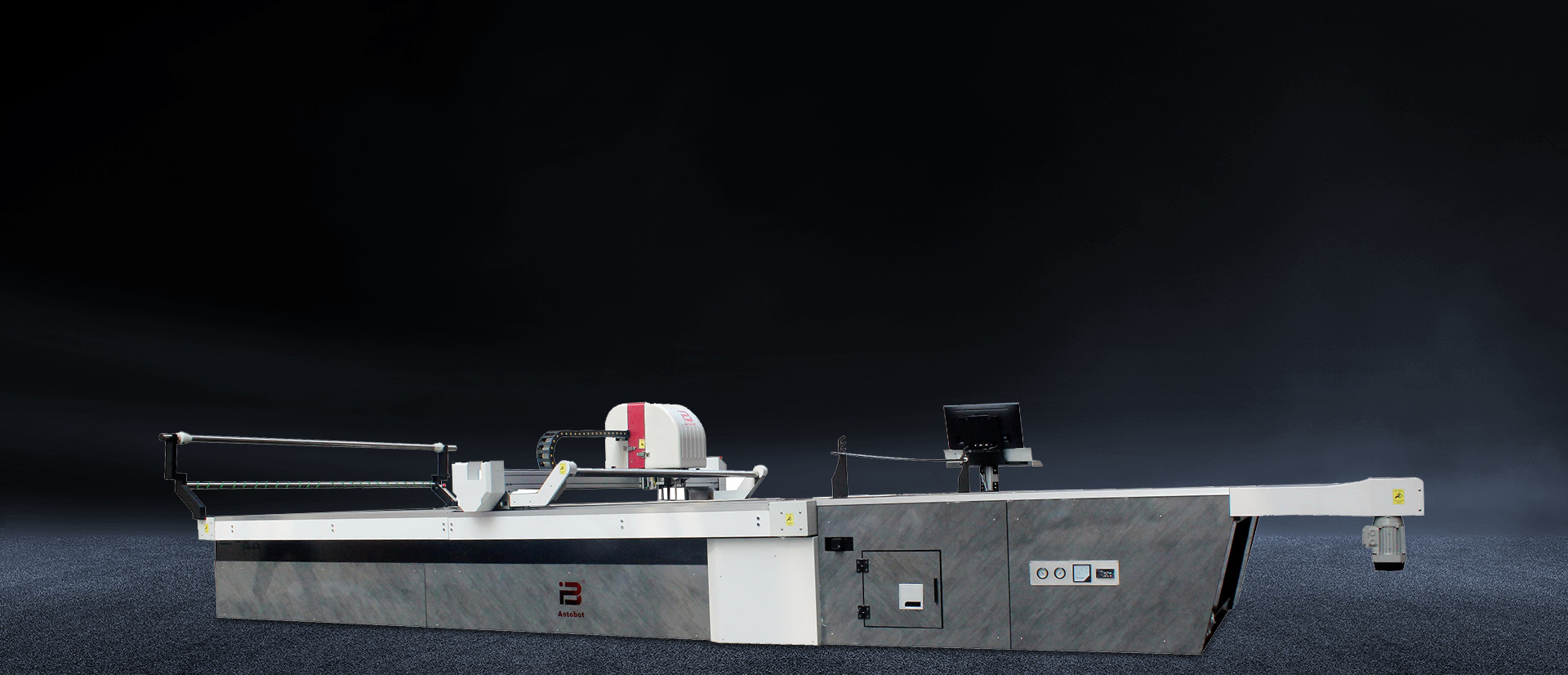

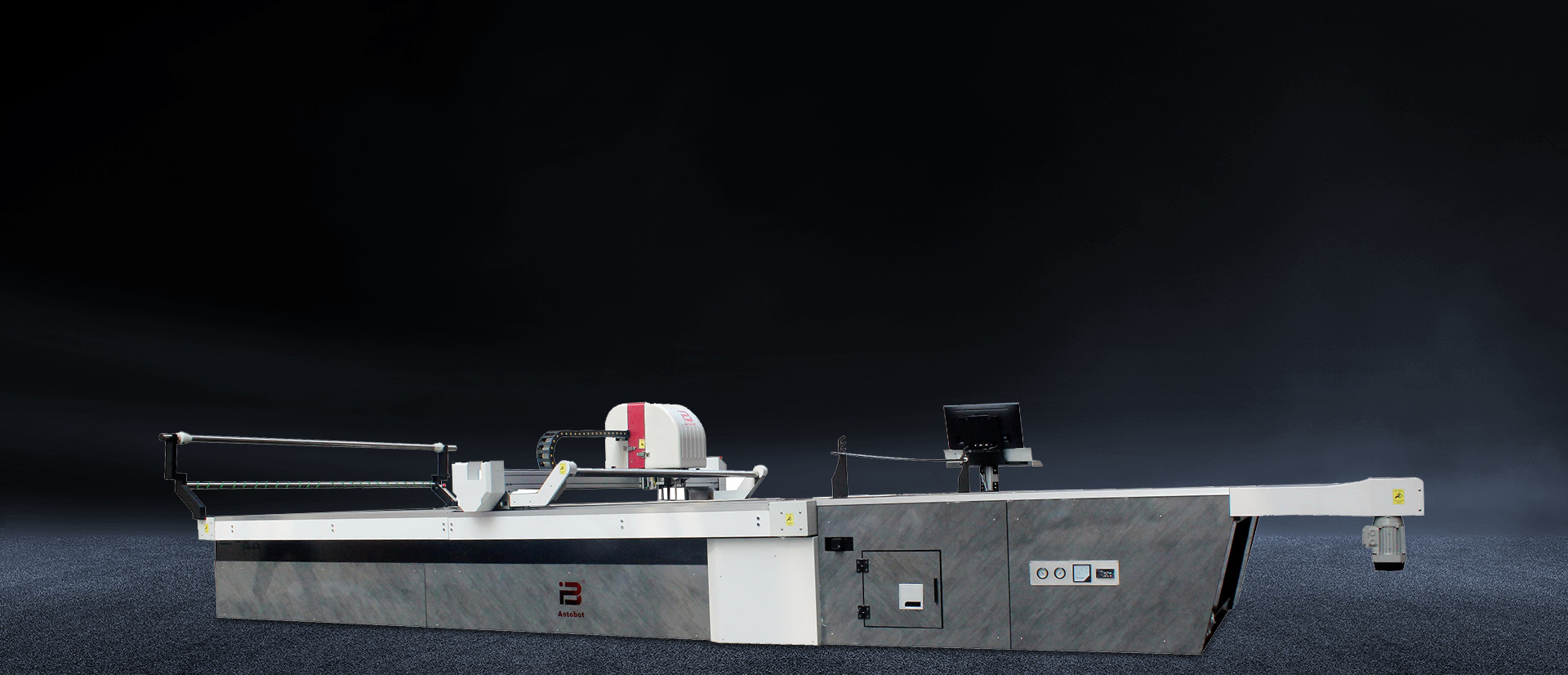

T-M11 cutting machine, the maximum cutting door width of 1.65 meters, the effective cutting window length reaches 3.0 meters, to meet the production needs of cutting pieces

◉ Automatic feeding unlimited cutting length, greatly improving work efficiency

◉ New blade locking function, the bottom of the blade floating in the fabric cutting

◉ Adsorption of automatic laminating, effectively improve the vacuum degree of cutting adsorption, to achieve stable fixation of the fabric

Advantageous Features

◉ Cutting speed 108m/min; industry-leading, 160-200 complete car seat covers per day

◉ Double knife disc cutting, high precision, V cutter two shoulders with the same height, other brands are difficult to achieve

◉ Double knife disc cutting, strong stability, very little mechanical wear and tear

◉ Table length of 3.0 meters without loss of cutting speed, can effectively improve the efficiency of 5% of work

◉ Low cost of use, excluding blades, paper, film consumables, not more than 20,000 a year

◉ Support optional 3 hollow punch

◉ Open design, with all the optional functions of the cutting machine

T-M11